Izindlela ezincane, ezibizwa ngokuthi amahinji omnyango, zibhekele ukusebenza kahle kweminyango yokujikisa. Idivayisi yabo elula kunikeza ukunyakaza kwamahhala komnyango ngesikhathi sokuvulwa nokuvalwa kwawo. Umshini osebenza ngokugcwele wenza kube lula ukusebenzisa iqabunga lomnyango, ngaphandle kokuhambisana nokunyakaza kwalo nganoma yikuphi ukwakheka nokukhanya kwangemuva. Okwamanje, amahenjisi eminyango asetshenzisiwe ekwakhiweni kwezikhala zokungena ezakhiweni nakufenisha. Kulokhu kokugcina, kusetshenziswa izindlela ezincane, kepha ngezimiso ezifanayo zokusebenza. Ukufakwa ngokwakho kwamahenjisi wefenisha kungadingeka uma kwenzeka ukufakwa okuzimele kweminyango emisha ekhabetheni lasekhishini noma ekhabethe lokulala kwenziwa. Ngaphandle kobukhulu bawo obuncane, amahinji ngesikhathi sokufakwa angadala ukuphazamiseka okuningi ngenxa yesidingo sezibalo ezinembile zamaphoyinti abo okulungiselela. Futhi, omunye umsebenzi kuzodingeka wenziwe ngesisindo, okuthi kwezinye izimo kungadinga ukubandakanyeka kwezandla ezengeziwe ukusiza ngezinto jikelele zefenisha.

Izici nezinhlobo

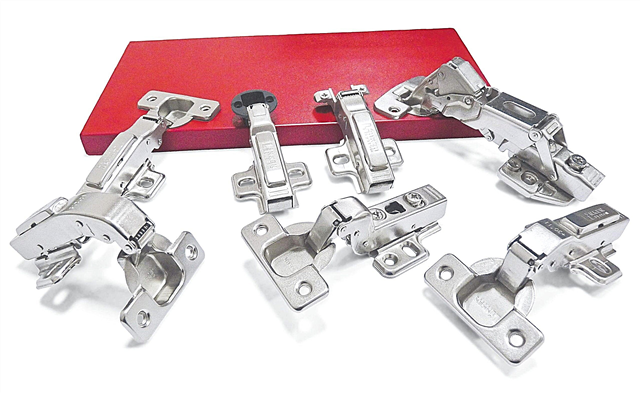

Ubulula nokusebenza kwendlela yehinge emnyango sekuveze izinhlobo zayo eziningi, ezakhelwe ukusetshenziswa ezinhlotsheni ezahlukahlukene zempahla yasendlini. Manje amadivayisi anjalo atholakala kokuhlukile okulandelayo:

- Ngaphezulu. Isetshenziswa kuma-wardrobe namakhabethe anezicabha zokujikisa;

- Kubekiwe. Okwezisekelo ezincane ezinesisindo somnyango ophansi;

- I-Calcaneal. Esetshenziswa kaningi eminyango yangaphakathi, angasebenza kahle kumakhabethe ane-facade encane;

- Amakhosi. Atholakala ematafuleni okusongwa ngokwakhiwa kwencwadi;

- Hlanganisa. Ifanele iminyango yamapaneli wamanga namaphaneli angahleliwe wezingubo zokugqoka ezishelelayo;

- Ikhona. Idizayinelwe izinhlobo ezihambisanayo zamagumbi afakwe emakhoneni egceke futhi anendawo elinganiselwe yokuvula iminyango;

- Ama-waybill ayisigamu. Zisetshenziswa kumakhabethe anenqwaba yezingqimba;

- I-Mezzanine. Zibuye zibe ngamahenjisi "avundlile" asetshenziswa ekulengiseni amakhabethe ekhishini.

Ukusetshenziswa kwalokhu noma lolo hlobo lwesicabha semnyango kwikhabethe kuncike ezintweni eziningi, kufaka phakathi isitayela sayo, ubukhulu, isisindo seminyango kanye nendlela eziboshwe ngayo. Kwezinye izimo, ngenxa yokubekwa ngokomzimba komnyango ohlobene nohlaka, isigqebhezana sidinga ukusetshenziswa kwamahenjisi ekhoneni kuphela, anendawo enkulu yokugcina amandla ngokuqhathanisa namahinji wendabuko ngaphezulu. Kumikhiqizo enokuthungwa okwakudala, kungasetshenziswa kuphela izindlela ezinjalo ezizohambisana nalesi sitayela.

Izinto ezidingekayo namathuluzi

Umsebenzi wokufaka ihenjisi lomnyango uzodinga ukuqaqa indlela yokusebenza, ngakho-ke awukwazi ukwenza ngaphandle kwamathuluzi wokwenza izinqubo ezibucayi. Ngaphezu kwalokho, abanye abakhohlisi bayadingeka emsebenzini ojwayelekile ngomnyango. Uhlu oluphelele lwawo wonke amathuluzi wokufaka imodeli ye-hinge ephezulu ngokulandelayo:

- Isikulufava sePhillips.

- Iqoqo lezikulufo.

- Izinga lokwakha.

- Irula noma itheyiphu isilinganiso.

- Iscrewdriver.

- Ukushayela.

- Ipensela noma umaka osusekayo.

- Milling umsiki nge ububanzi of 35 mm.

Ukuhlelwa kwe-hinge okujwayelekile kubandakanya ukuyiqaqa ibe izingxenye ezintathu:

- Isisekelo sisesimeni somucu, esibhekele ukubophela ihibe kuphaneli lekhabethe.

- Inkomishi, ebekwe emnyango osebenzayo.

- Umzimba womnyango yingxenye esuswayo ehlanganisa umnyango nomzimba wekhabethe.

Umshini womnyango wesicabha ufakwa ngezikulufi zokubopha ezifakwe emigodini yepuleti nenkomishi ekhuphukayo. Isikulufu sokulungisa kuleli cala sibhekene nemingcele yedivayisi. Ngakho-ke, umshini we-hinge unezihlanganisi ezidingekayo ezingafika kweziyisithupha, ezilungiswa kahle kusengaphambili njengeziphephile.

Imakhaphu

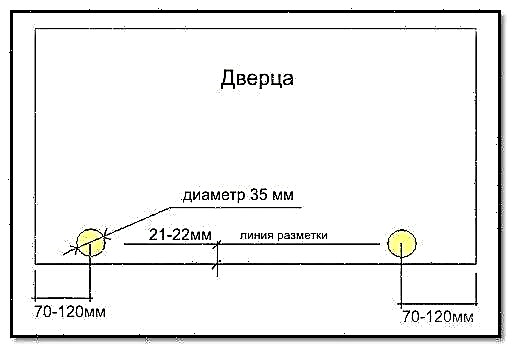

Ukumakwa kuyingxenye ebalulekile yokwakheka kwekhabethe ukufakwa kahle komnyango nokusebenza ngokufanele kwamahinji alo. Amaphutha enziwe kulesi sigaba okungenani azokonakalisa ukubonakala komkhiqizo, njengobukhulu - akwenze kungabi lula ukusebenzisa kahle indlela yomnyango wejingi. Ngenqubo yokumaka, uzodinga ipensela noma umaka, ozomaka izindawo zokwakha izimbobo zezinkomishi zomshini. Ngakho-ke, kufanelekile ukuqala ngamaphoyinti abalulekile emiyalo ye-markup:

- Ngokuya ngesisindo nobukhulu beqabunga lomnyango, inani lamahinjiji afakiwe lingahluka kusuka kokumbili kuye kwemihlanu.

- Akudingekile ukufaka inkomishi yomshini onqenqemeni lwangaphambili lomnyango. Kunconywa ukugcina i-indent engu-2-2.2 cm.

- Ibanga elijwayelekile phakathi kwamahabhinisi ehlangothini lomnyango ubude bemitha okungenani li-50 cm.Ngasikhathi sinye, kufanele kubhekwe isisindo salo, esingadinga inani elikhulu lezindlela zokubopha.

Qiniseka ukuthi izindawo zokufaka amahenjisi ku-facade azikho phambi kwamashalofu ekhabethe. Ngaphandle kwalokho, kunengozi yokuthi umnyango ngeke uvalwe ngokuphelele ngenxa yokuthi umzimba uhlala endaweni yeshalofu.

Ukulungiswa kweHole

Izimbobo zenziwa nge-drill ngokususelwa kokumaka. I-screwdriver kagesi enokunamathiselwe okufanele nayo kufanelekile njengethuluzi elinye. Ngaphezu kwalokho, okudingekayo ukusetshenziswa kokusika, okuqinisekisa ubuqotho besakhiwo sesango lomnyango kanye nephaneli lekhabethe. Uma kungenjalo, ukubhoboza umgodi kungaholela kuma-chips nokuguquguquka kwephaneli lezinkuni. Okufakiwe kufanele kwenziwe kungabi ngaphezu kwe-12 mm ukujula, okuzokwanela umgodi ovikelekile wesikhulumi sendebe ye-hinge. Kungcono ukhethe isivinini sokubhola ngokwakho, ngokuya ngobuningi bezinto lapho kwenziwa khona i-facade nekhabethe. Uma amapaneli we-chipboard elula ngokwanele ekucubungulweni okunjalo, ama-walnut wemvelo noma umlotha uhlukaniswa ngezinkomba zamandla aphezulu. Ngesizathu esifanayo, kufanele uqinisekise ukuthi i-drill isebenza ngokuqinile e-engeli lama-degree angama-90, lapho ingaphambuka kalula uma ubhekene nokhuni lwemvelo oluqinile.

Ukubopha iluphu

Ngenxa yokuthi iqabunga lomnyango eliyinto ehambayo, ngokungafani nekhabethe, udinga ukuqala ukulungisa ihinsi kuyo. Lokhu kuzokwenza umsebenzi wakho ube lula ngokususa isidingo sokulungisa i-facade kumahinji lapho kufanele uyilengise. Umsebenzi wokufaka ngezinqubo ze-swing ungenziwa ngokuya ngemiyalo elandelayo:

- Esigabeni sokufaka ihinji lomnyango, onke amaphutha wokumaka nokusebenza emigodini angavela uma uqala ukuwusebenzisa lapho uzofakwa khona ngokuzayo. Zama ukwenza isheke elifanayo kusengaphambili, uqiniseke ukuthi ipulatifomu yenkomishi ye-patch hinge ilingana kahle ebusweni beqabunga lomnyango kuyo yonke indawo yayo. Ngisho nokuphambuka okuncane kakhulu kungadala ukuthi umnyango uphenduke ngokuzayo.

- Kusetshenziswa ipensela nokufaka iluphu, kwenziwa ukumakwa okusha ngezikulufo ukuze zilingane ngqo emiphakathini yeluphu.

- Ngemuva kwalokho, ungafaka ipulatifomu ekugcineni ngokuskena kwizibopho nge-screwdriver noma i-screwdriver.

Ngaphambili ilenga

Ubulukhuni balesi sigaba somsebenzi busesidingo sokulengisa ngesandla iqabunga lomnyango ngamabheji afakiwe ukuze imizimba yabo iwele ngaphansi kwamapulatifomu abekwe kupaneli lekhabhinethi. Wonke umsebenzi wokufaka wenziwa ngokulandelana okulandelayo:

- Uma kunokwenzeka, jikela iKhabhinethi endaweni eqondile. Lokhu kuzokwenza lula inqubo yokuzama ku-facade yokuqhubeka nokufakwa.

- Usebenzisa ipensela, dala umaki wamapuleti wokufaka wesikhathi esizayo, lapho kuzofakwa khona izindlela zehinge.

- Beka amapulangwe ngqo ngaphansi kokumaka futhi uvikelekile ngezikulufu zokuzishaya usebenzisa i-screwdriver.

- Faka umnyango ohlangothini lwekhabhinethi, uqaphele ukuthi ungaphambuki ezikhundleni ezimakiwe zamahinji.

- Ungaqala umhlangano ophelele wama-hinge ngokuxhuma amapulatifomu abo ngaphambili nangaphansi usebenzisa i-case. Umphumela uba izindlela zokushwibeka ezenziwe ngomumo, ezilungele ukuhamba.

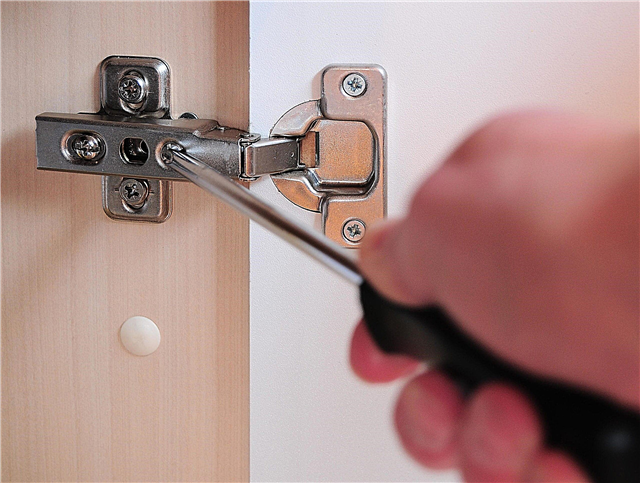

- Esigabeni sokugcina, uzodinga ukulungisa ihenjisi usebenzisa i-screwdriver. Indima enkulu kulo msebenzi izodlalwa isikulufa esihambelanayo ezindlini zesakhiwo esiphakathi sendlela.

Ukulungiswa kwezinkinobho

Ngaphandle kokuthi abanye abasebenzisi benza inqubo yokulungisa "ngamehlo" lapho iqabunga lomnyango wekhabethe lingakafakwa esakhiweni sefenisha, le ndlela ayinakubizwa ngokuthi ilungile. Ngokuqala isinyathelo sokulungisa ngemuva kokulengisa i-facade, uzothola isithombe esiphelele sokuthi ukuphathwa kwakho nge-hinge adjusting screw kuzokuthinta kanjani ukubukeka nokusebenziseka kalula komnyango. Lungiselela kusengaphambili iqiniso lokuthi kuzothatha amahlandla ambalwa ukukhululeka nokuqinisa isikulufa ezindlini zomshini ngaphambi kokuba ufike endaweni ekahle yeqabunga lomnyango. Ngokwenza lokho, kunconywa ibhukwana kunokuba ithuluzi lokuzenzekelayo, yingakho kungcono ukukhetha isikulidilayiva sePhillips. I-screwdriver, yize ikwazi ukuphatha isikulufu ngokushesha okukhulu, ingahle ilayishe ingxenye futhi isule ikhanda layo. Kuzodingeka ukwenza ukulungisa ngokuya ngamapharamitha amathathu wendawo ye-facade, okuzoxoxwa ngayo kabanzi ngezansi.

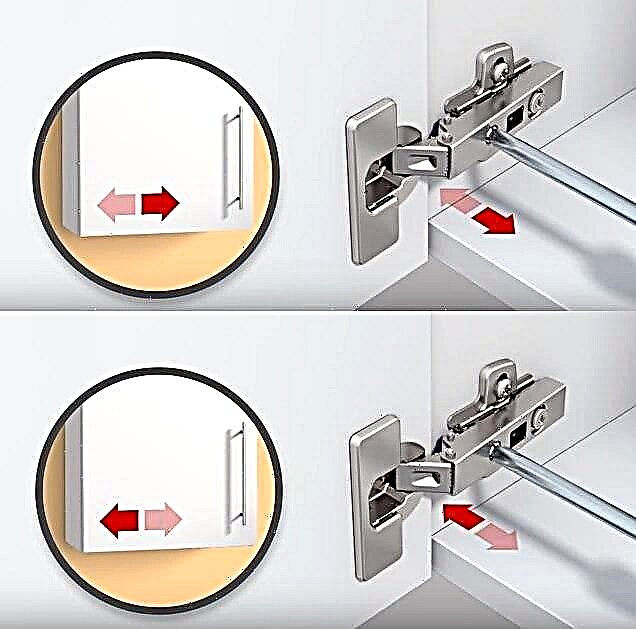

Ukulungiswa kokuhluka okuvundlile

Ukuma kweqabunga lomnyango kulungiswa ngokuligudlulela kwesobunxele noma kwesokudla. Umgomo wakho wokugcina ukugwema izikhala ezinkulu kakhulu phakathi kwengaphambili nephaneli lekhabhinethi. Uyacelwa ukuthi uqaphele ukuthi igebe elincanyana kakhulu lizokwenza kungakwazi ukuthi umnyango uhambe nge-eksisi yomnyango wawo. Futhi, ukulungiswa kuyadingeka emakamelweni anezindonga ezingezona ezijwayelekile, lapho ikhabethe lingabekwa khona engeli ethile.

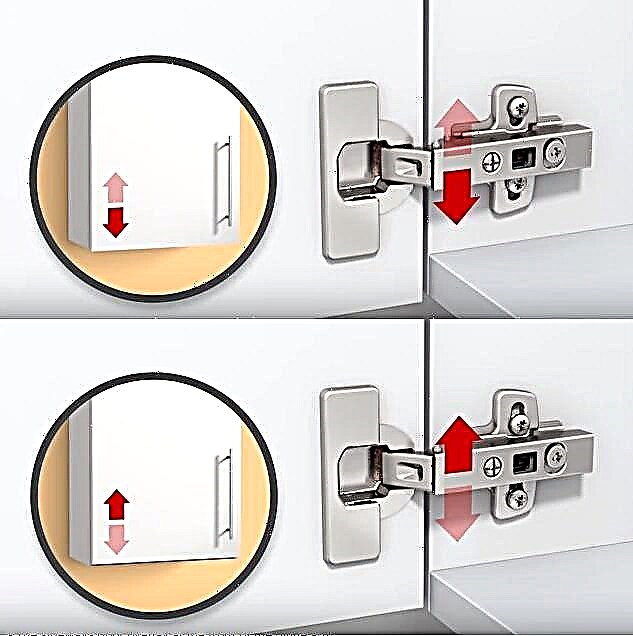

Ukulungiswa okuqondile

Ngokuphambene nokulungiswa okuvundlile, ukulungiswa okuqondile mpo phezulu kwenziwa ngokukhohlisa okwe-oval ku-hinge mechanism. Umehluko olandelayo kusuka enkambisweni yokulungiswa enezingqimba iqiniso lokuthi ukuma okuqondile kwe-facade kungakwazi "ukuxega" ngokuhamba kwesikhathi ngenxa yethonya eliqhubekayo lamandla adonsela phansi. Ngalesi sizathu, ukulungiswa okuqondile kufanele kwenziwe njalo.

Ukulungiswa kokujula komnyango

Ukujula kusho ukulungisa isikhundla somnyango esihlobene nomzimba wekhabhinethi, nakho okuthinta igebe phakathi kwabo. Kubasebenzisi abaningi, inqobo nje uma efakwe kahle futhi amakwa kahle, lolu hlobo lokulungiswa cishe aludingeki. Esikhathini esiningi, ukulungiswa kwe-facade kwenziwa emakamelweni anezitezi ezingalingani, okungadala ukunyakaza komnyango okuyinkimbinkimbi.

Ukuhlanganisa okokufaka izivalo ezingilazini

Ngokwanda okukhulayo kwefenisha yengilazi enomoya omnene, uhla lwezinto ezifakwayo ezingasebenza kahle nalokhu kwaziswa nalo luye lwanda. Ngaphandle kokukhuphuka kwamanani wamandla uma kuqhathaniswa nengilazi yendabuko, ingilazi enomoya usesengozini enkulu ekucindezelekeni komshini kunamapaneli wokhuni kanye ne-chipboard. Ngakho-ke, izinhlobo ezahlukanisiwe zamahinsi ezinohlobo oluhlukile ngokuqinile lwezinto zokubopha zenzelwe iminyango yalolu daba. Umehluko wokuqala phakathi kwalezi zinqubo amandla abo akhuphukile nomthamo womthwalo ngenxa yesisindo esikhulu sengilazi. Izinsimbi ezilandelayo zisetshenziswa enhliziyweni yamabhince omnyango wengilazi:

- Ithusi;

- I-aluminium;

- Ingxubevange yeZinc;

- Ingxubevange yensimbi engagqwali.

Ngokwesimiso sokubopha, izindlela ze-hinge zingaba ngaphezulu noma ekufeni. Lokhu okwedlule ngokwesiko kudinga ukwakhiwa kwezimbobo zokulungisa izikulufo, kuyilapho abangaphambilini bethembele ekubambeni ingilazi engaphambili ngengcindezi ephezulu kuyo. Kulokhu, i-overhead ingasebenza kumgomo wokunamathela amapulatifomu ezinhlangothini zombili zomnyango wengilazi noma ukusebenzisa izikulufu zokulungisa ezicindezela i-facade ngaphakathi kwendlela ye-hinge.

Isiphetho

Ukuze kuqinisekiswe ukusebenza kahle kweminyango ye-swing ezinhlotsheni eziningi zefenisha yasekhaya, amahinji adinga ukubalwa okuqondile ngesikhathi senqubo yokufaka. Ngokulandela imiyalo enikeziwe, uzokwazi ukufaka ngempumelelo ama-facade ezinhlotsheni ezahlukahlukene zamakhabethe nabagqoka. Ukulungiswa kahle kwephrofayili yalezi zinqubo kuzonikeza umnyango ukunyakaza kwamahhala nokulungiswa okuqinile emzimbeni womkhiqizo wefenisha endaweni evaliwe. Ukuqedela zonke izigaba zomsebenzi, osonkontileka ababizayo abavela eceleni nokusetshenziswa kwamathuluzi angavamile akudingeki. Kungenzeka ukufaka ama-swing hinges ngisho nangaphandle kwemishini ezenzakalelayo njenge-screwdriver, usebenzisa i-screwdriver yakudala.